Feb 25 , 2026

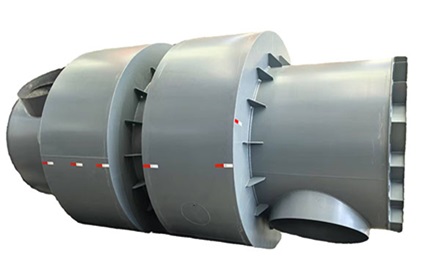

The sulfuric acid heat exchanger is a crucial component in many industrial processes, particularly in chemical and petrochemical plants, where sulfuric acid is used in a variety of applications, including sulfur recovery and acid production. Given the corrosive nature of sulfuric acid, maintaining a sulfuric acid heat exchanger is vital to ensure its long-term performance, safety, and efficiency. Proper maintenance practices not only help extend the lifespan of the equipment but also improve energy efficiency, reduce downtime, and ensure compliance with environmental regulations.

One of the most important maintenance practices for a sulfuric acid heat exchanger is regular inspection and cleaning. Over time, the accumulation of sulfuric acid deposits, salts, and scale can lead to reduced heat transfer efficiency, blocked passages, and even corrosion of the internal components. Routine inspections should focus on checking for leaks, cracks, or any signs of physical damage. Visual inspections, combined with pressure and temperature tests, can help identify any operational issues early on.

Cleaning is equally important, as buildup of impurities can obstruct fluid flow, increasing the risk of overheating and pressure drops. Cleaning methods for sulfuric acid heat exchangers vary depending on the system's design and the level of fouling. In many cases, chemical cleaning or the use of high-pressure water jets is effective in removing deposits and restoring the heat exchanger's performance. Additionally, ensuring that the cleaning process is safe and that the correct cleaning agents are used is crucial to avoid damaging the equipment or affecting the performance of the sulfuric acid heat exchanger.

The operation of a sulfuric acid heat exchanger is inherently prone to corrosion due to the aggressive nature of sulfuric acid. As sulfuric acid reacts with metals and alloys, it can cause thinning of the metal surfaces, leading to leaks and reduced heat transfer efficiency. Routine monitoring of the heat exchanger's performance is essential to detect early signs of corrosion. Regular inspection of the tubes, seals, and connections will help identify any corrosion or degradation before it leads to more significant issues.

To prevent corrosion, many sulfuric acid heat exchangers are made from corrosion-resistant materials such as titanium or high-grade stainless steel. However, even these materials can deteriorate over time, especially under high temperatures and pressures. One important practice in maintenance is to ensure that the materials used are suitable for the specific sulfuric acid concentration and temperature conditions in the system. In some cases, protective coatings or linings may be applied to prevent corrosion and extend the service life of the equipment.

In addition to physical inspections, it's important to monitor the temperature and pressure levels in the system closely. Exceeding recommended operating conditions can accelerate corrosion and wear. Temperature and pressure sensors should be checked regularly to ensure they are functioning correctly and providing accurate data.

Proper flow distribution within the sulfuric acid heat exchanger is essential for maintaining optimal heat transfer efficiency. Uneven flow distribution can cause hot spots, increased wear, and less efficient heat transfer. Maintaining consistent flow is important to ensure that the heat exchanger operates efficiently and that the sulfuric acid is evenly distributed across the heat transfer surfaces.

One common maintenance issue is the buildup of scale or fouling on the heat exchange surfaces, which impairs heat transfer. To prevent this, regular cleaning is necessary, as mentioned earlier. Additionally, ensuring the proper configuration of the heat exchanger and regularly checking for any obstructions in the flow paths can help maintain consistent performance. Over time, gaskets, seals, and other components may wear down, causing leaks or reduced efficiency. Regular maintenance checks to replace or repair these parts will ensure optimal performance and reduce the likelihood of downtime.

As sulfuric acid heat exchangers operate under harsh conditions, certain components may wear out over time. Regularly scheduled replacement of these parts is essential to prevent unexpected failures and extend the lifespan of the equipment. Parts that are prone to wear include seals, gaskets, valves, and even some of the internal heat exchange surfaces.

It's important to keep track of sulphuric acid plant manufacturers' recommendations regarding the expected lifespan of different components. Parts that come into direct contact with sulfuric acid or experience high temperatures may need to be replaced more frequently. By keeping a record of component replacements and routinely replacing worn parts, you can prevent unscheduled downtime and improve the overall reliability of the sulfuric acid heat exchanger.

Proper training for operators is an often-overlooked aspect of sulfuric acid heat exchanger maintenance. Ensuring that personnel understand the correct operational procedures, maintenance protocols, and safety measures can prevent accidents and enhance the performance of the equipment. Given the corrosive nature of sulfuric acid, workers should be trained to handle leaks or spills, perform emergency shutdowns, and wear proper protective gear.

Operators should be familiar with the symptoms of malfunctioning heat exchangers, such as unusual temperature fluctuations, pressure changes, or abnormal noise, and know how to take corrective action immediately. Furthermore, having a well-established maintenance schedule and keeping detailed records of all maintenance activities helps track the health of the equipment and facilitates quicker identification of potential problems.

Maintaining a sulfuric acid heat exchanger is essential for ensuring the continued efficiency and safety of industrial processes involving sulfuric acid. By implementing regular inspection, cleaning, monitoring for corrosion, ensuring proper flow distribution, and replacing worn-out parts on schedule, facilities can extend the lifespan of their heat exchangers and avoid costly downtime. Moreover, investing in operator training and safety practices will contribute to the smooth and efficient operation of sulfuric acid heat exchangers. Regular and systematic maintenance not only boosts performance but also ensures the safety of both the equipment and the personnel operating it.

This is the first one.